In the global vegetable oil processing industry, procurement officers and decision - makers face a multitude of challenges. The rising demand for high - quality vegetable oils, combined with the need for cost - effective production methods, has put pressure on manufacturers to find innovative solutions. According to industry reports, the global demand for vegetable oil is expected to grow at a CAGR of 3.5% over the next five years. This growth requires more efficient extraction technologies to meet the market needs.

The advanced solvent extraction technology in vegetable oil production lines offers significant improvements in oil yield and product quality. In comparison with traditional extraction methods, this technology can increase the oil yield by up to 10%. For example, in a medium - sized soybean processing plant, the application of this advanced technology has increased the daily oil output from 50 tons to 55 tons, a remarkable 10% increase. Moreover, the quality of the extracted oil is superior, with lower impurity levels and better nutritional profiles.

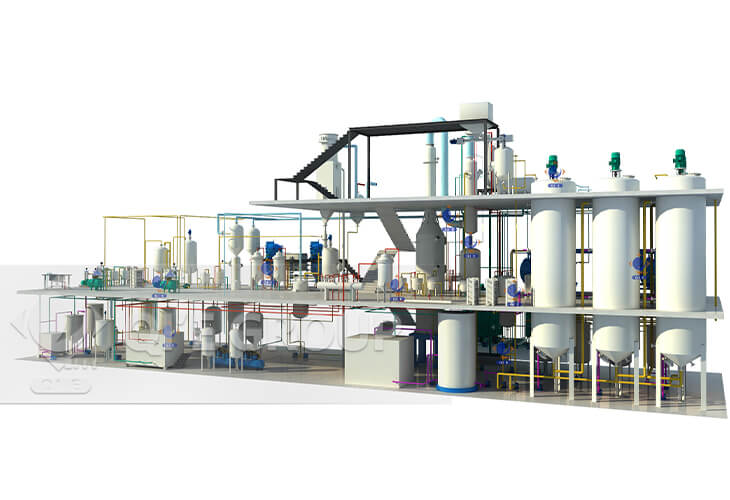

This production line is designed for ease of operation and low maintenance costs, making it an ideal choice for medium and large - scale processing plants. The simple operation process reduces the need for highly skilled labor, and the maintenance cost is 20% lower than that of traditional production lines. For instance, in a large - scale palm oil processing factory, the annual maintenance cost has been reduced from $100,000 to $80,000 after adopting this production line.

The equipment in this production line is of high quality, backed by international quality certifications such as ISO 9001 and CE. Rigorous testing reports show that the failure rate of the equipment is less than 1%, ensuring stable and long - term operation.

The automatic control system in the production line operates on a sophisticated algorithm. It can monitor and adjust key parameters such as temperature, pressure, and solvent flow rate in real - time. This not only improves production efficiency but also ensures product consistency. For example, the system can maintain the extraction temperature within an accuracy of ±1°C, resulting in a more stable oil quality.

After - sales service is crucial for any production line. Our company provides 24/7 technical support and on - site maintenance services. A customer from South America reported that when their production line encountered a problem, our technical team arrived at the site within 48 hours and resolved the issue promptly, minimizing the production downtime.

We offer customization services to meet the specific needs of different customers. We have successfully customized production lines for various raw materials, such as rapeseed, sunflower seeds, and rice bran. For example, a customer in Southeast Asia needed a production line for rice bran oil extraction. We customized a production line that met their specific requirements, and the customer was highly satisfied with the results.

Contact us today to learn more about our advanced vegetable oil production line with solvent extraction technology. Our team of experts is ready to provide you with detailed information and customized solutions. Click here to start the conversation or fill out the form below to get a free consultation.