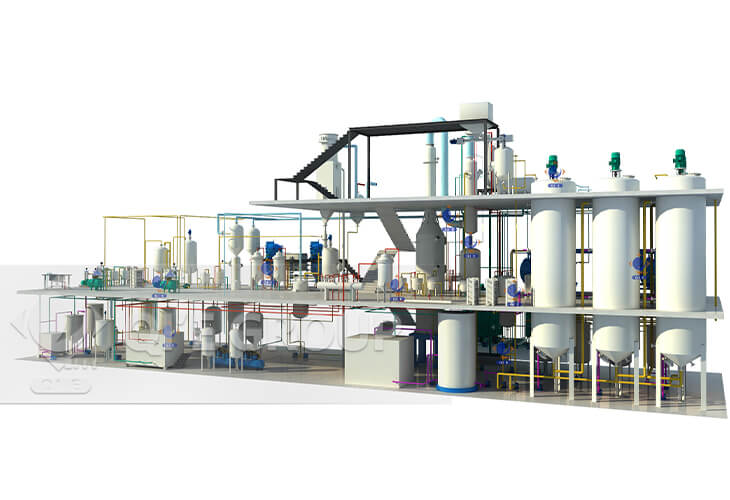

The production of rice bran oil involves a series of complex processes, from raw material pretreatment to the final refined product. Understanding the overall process is crucial for optimizing production efficiency and ensuring high - quality oil. The general process starts with the collection of rice bran, followed by cleaning, conditioning, and then solvent extraction. After extraction, the crude oil undergoes refining steps such as degumming, deacidification, decolorization, and deodorization.

Pretreatment equipment plays a vital role in preparing rice bran for extraction. Cleaning equipment is used to remove impurities such as dust, stones, and husks, which can affect the extraction efficiency and oil quality. Conditioning equipment adjusts the moisture content and temperature of the rice bran, enhancing the permeability of the solvent during extraction. When selecting pretreatment equipment, factors such as processing capacity, energy consumption, and ease of maintenance should be considered. For example, a cleaning machine with a processing capacity of 5 - 10 tons per hour is suitable for medium - sized rice bran oil production plants.

Extraction equipment is at the heart of the rice bran oil production process. Solvent extraction is a widely used method due to its high efficiency and ability to obtain a high yield of oil. The extraction equipment uses solvents to dissolve the oil in the rice bran, and then separates the oil - solvent mixture from the solid residue. The extraction rate can reach up to 95% with advanced extraction equipment. The choice of extraction equipment depends on the scale of production and the type of solvent used. Continuous extraction equipment is more suitable for large - scale production, while batch - type equipment is suitable for small - scale operations.

Refining equipment is essential for improving the quality of crude rice bran oil. Degumming equipment removes phospholipids and other impurities, deacidification equipment reduces the free fatty acid content, decolorization equipment removes pigments, and deodorization equipment eliminates unpleasant odors. The refining process can significantly improve the clarity, stability, and flavor of the oil. For instance, after decolorization, the color value of the oil can be reduced from 30 - 40 (Lovibond scale) to less than 5, making the oil more marketable.

Auxiliary equipment, such as pumps, heat exchangers, and storage tanks, provides necessary support in the entire rice bran oil production process. Pumps are used to transfer materials between different equipment, heat exchangers are used to control the temperature of the materials, and storage tanks are used to store the intermediate and final products. The proper selection and operation of auxiliary equipment are crucial for the smooth operation of the production line.

Intelligent technology has brought significant improvements to rice bran oil production equipment. For example, intelligent control systems can monitor and adjust the operating parameters of the equipment in real - time, such as temperature, pressure, and flow rate. This not only improves production efficiency but also reduces energy consumption. In some advanced production lines, the use of intelligent technology has increased the production efficiency by 20% and reduced energy consumption by 15%.

Regular equipment maintenance is essential for ensuring long - term stable operation and high production efficiency. This includes cleaning, lubrication, inspection, and replacement of worn - out parts. Optimization strategies such as process parameter adjustment and equipment upgrade can also further improve production efficiency. For example, by adjusting the solvent - to - material ratio in the extraction process, the extraction efficiency can be increased by 5 - 10%.

Are you looking to enhance your rice bran oil production? Our advanced equipment and intelligent solutions can help you achieve higher efficiency and better product quality. Click here to learn more about our products and services.