Mustard oil is a versatile product widely used in the culinary world and traditional medicine. In the global market, the demand for mustard oil has been steadily increasing, with an estimated annual growth rate of 5% in recent years. This growth has led to a surge in the number of mustard oil extraction plants, each striving to optimize their production processes for higher efficiency and better product quality.

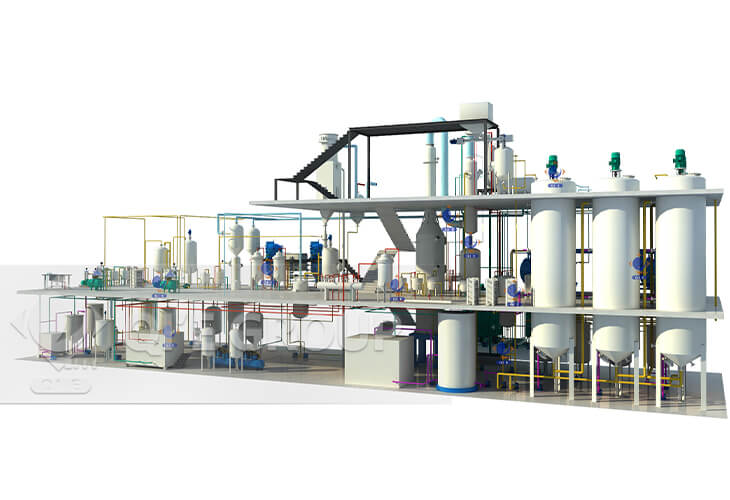

The key to a successful mustard oil extraction plant lies in the proper matching of equipment with the extraction process. Different extraction methods require specific types of equipment, and the right combination can significantly impact the quality, quantity, and cost of production.

Cold pressing is a traditional method that involves crushing mustard seeds at low temperatures, typically below 49°C. This method preserves the natural flavor and nutritional value of the oil. However, it has a lower extraction rate, usually around 30 - 35%. The equipment for cold pressing mainly includes hydraulic presses and screw presses. These presses need to have high precision and strong pressure - bearing capacity to ensure efficient extraction.

Hot pressing involves heating the mustard seeds before pressing. This method can increase the extraction rate to 40 - 45%. By heating the seeds, the oil viscosity decreases, making it easier to separate from the seeds. However, high - temperature processing may cause some loss of nutrients and change the flavor of the oil. The equipment for hot pressing requires good temperature control systems to maintain the appropriate pressing temperature.

Solvent extraction is a more efficient method, with an extraction rate of up to 90%. It uses solvents such as hexane to dissolve the oil from the mustard seeds. After extraction, the solvent is removed through evaporation. This method can obtain a large amount of oil, but it requires strict safety measures due to the flammability of solvents. The equipment for solvent extraction includes extractors, evaporators, and condensers, which need to be corrosion - resistant and air - tight.

When selecting mustard oil extraction equipment, several factors need to be considered. Performance is crucial, including extraction rate, production capacity, and energy consumption. Quality is also important, as high - quality equipment can ensure stable operation and long - term use. Cost is another key factor, including purchase cost, operating cost, and maintenance cost. It is estimated that high - quality equipment can reduce maintenance costs by up to 30% over a five - year period.

Regular equipment maintenance can extend the service life of the equipment and ensure stable production. Updating equipment in a timely manner can also improve production efficiency and product quality. For example, upgrading the extraction equipment can increase the extraction rate by 5 - 10%.

A mustard oil extraction plant in India successfully increased its production efficiency by 20% and improved product quality by matching the appropriate equipment with the extraction process. This case shows that proper equipment - process matching can bring significant benefits.

In conclusion, the matching of mustard oil extraction equipment with the extraction process is a critical factor for the success of mustard oil extraction plants. It can improve production efficiency, product quality, and reduce costs. By focusing on this aspect, mustard oil extraction plants can enhance their brand competitiveness in the global market.

Contact us now to explore our range of high - quality mustard oil extraction equipment and find the perfect match for your extraction process. Elevate your brand's market presence and competitiveness with our professional solutions.