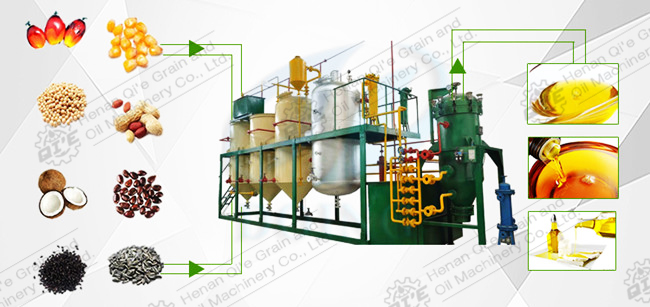

In the realm of industrial sunflower oil production, an efficient, safe, and compliant solvent extraction system is crucial for maximizing productivity and ensuring product quality. This article comprehensively presents a solution for such a system in export-oriented sunflower oil production lines, aiming to provide authoritative technical guidance for industrial producers.

The solvent extraction method is a widely used technique in sunflower oil production. At its core is the hexane extraction principle. Hexane, a highly effective solvent, can dissolve the oil in sunflower seeds efficiently. The extraction equipment is designed with precision to ensure maximum contact between the solvent and the raw material. For example, the design of the extraction vessel allows for a uniform distribution of hexane, enhancing the extraction efficiency. In a well - designed system, the extraction rate can reach up to 95%, which is significantly higher than traditional methods.

The desolventizing process is another key aspect. It involves removing the hexane from the extracted oil and the meal. Precise control of temperature and pressure during this process is essential to maintain the quality of the oil and meal. A properly controlled desolventizing process can reduce the hexane residue in the oil to less than 10 ppm, meeting international safety standards.

The oil content and particle size of sunflower seeds have a significant impact on the oil extraction efficiency. Empirical data shows that sunflower seeds with an oil content of 40 - 50% are most suitable for solvent extraction. When the particle size is between 0.5 - 1 mm, the contact area between the solvent and the seeds is maximized, leading to a higher extraction rate. For instance, in a study of 10 different batches of sunflower seeds, those with the optimal particle size and oil content achieved an average extraction rate of 92%, while others had rates ranging from 80 - 85%.

| Oil Content (%) | Particle Size (mm) | Extraction Rate (%) |

|---|---|---|

| 40 - 50 | 0.5 - 1 | 92 |

| 30 - 40 | 1 - 2 | 85 |

| 20 - 30 | 2 - 3 | 80 |

Safety and environmental protection are of utmost importance in the sunflower oil production process. The use of hexane requires strict safety protocols. For example, all equipment must be properly grounded to prevent static electricity, and ventilation systems should be in place to ensure the safe dispersion of hexane vapor. In terms of environmental protection, the solvent recovery rate should be above 98% to minimize waste and environmental pollution.

Several large - scale grain and oil processing enterprises have successfully implemented this solvent extraction system. For example, Company A reduced its energy consumption by 30% and labor costs by 25% after adopting the system. This not only improved its production efficiency but also enhanced its market competitiveness. By using advanced technology and equipment, these enterprises can produce high - quality sunflower oil at a lower cost, meeting the growing demand in the international market.

Our company offers professional sunflower oil extraction machinery that incorporates all the above - mentioned technologies and advantages. If you are looking to improve your sunflower oil production line, enhance efficiency, and reduce costs, our products are the ideal choice. Click here to learn more about our sunflower oil extraction machinery and take the first step towards a more profitable and sustainable production process.