Rice bran oil expansion equipment is the core machinery in the rice bran oil production process, playing a crucial role in enhancing oil extraction rate and production capacity. The expansion machine operates based on the principle of mechanical extrusion and high - temperature steam treatment. When the rice bran enters the expansion chamber, it is subjected to high pressure and temperature, which causes the physical and chemical changes of the rice bran. For example, the cell structure of the rice bran is broken, making it easier to extract oil.

In the operation of the expansion machine, the control of core process parameters such as temperature, pressure, and moisture is of great significance. According to industry experience, the optimal temperature range for rice bran oil expansion is usually between 110 - 130°C. If the temperature is too low, the expansion effect will be poor, and the oil extraction rate will be affected. When the temperature is too high, it may cause the deterioration of the oil quality. As for pressure, it is generally maintained at 3 - 5 MPa to ensure the normal operation of the expansion process.

Moisture content also has a significant impact on the expansion effect. The moisture content of rice bran before entering the expansion machine is preferably controlled at about 10% - 12%. By adjusting these parameters, the oil extraction rate can be increased by about 2% - 3% compared with the non - optimized process.

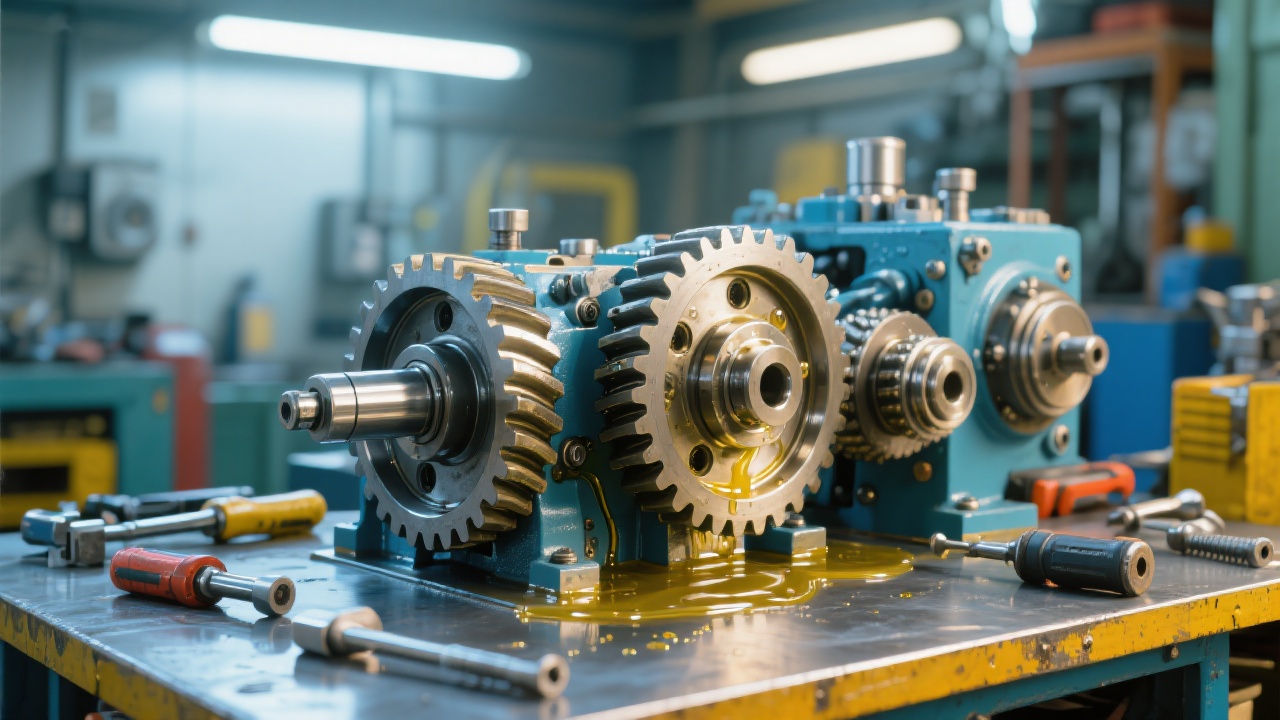

The materials and design structures of the expansion machine have a direct impact on the processing effect. For example, expansion machines made of high - quality alloy steel have better wear resistance and corrosion resistance, which can extend the service life of the equipment. In terms of design structure, the expansion chamber with a reasonable screw pitch and diameter ratio can ensure the uniform mixing and extrusion of rice bran, thereby improving the expansion quality.

In the actual operation of rice bran oil expansion equipment, energy - saving and emission - reduction are important considerations. One effective method is to use waste heat recovery technology. By recovering the waste heat generated during the expansion process, it can be reused for pre - heating the rice bran or other production processes, which can save about 15% - 20% of energy consumption. In addition, optimizing the operation process, such as reducing the idle running time of the equipment, can also achieve the purpose of energy conservation.

To improve the production capacity, enterprises can start from two aspects: equipment upgrading and process optimization. Upgrading the equipment, such as increasing the diameter of the expansion chamber and the power of the driving motor, can directly increase the processing capacity of the equipment. At the same time, optimizing the feeding speed and the coordination between different processes can also improve the overall production efficiency. For example, a well - coordinated production line can increase the production capacity by about 20% - 30%.

In recent years, the intelligent and environmental protection trends in the industry have had a profound impact on the selection of rice bran oil expansion equipment. Intelligent equipment can realize real - time monitoring and automatic control of process parameters, which improves the accuracy and stability of production. Environmental - friendly equipment can reduce pollution emissions and meet the requirements of sustainable development. Therefore, when selecting equipment, enterprises should give full consideration to these trends to enhance their competitiveness in the market.

In conclusion, the selection and application of rice bran oil expansion equipment require comprehensive consideration of multiple factors. By understanding the working mechanism, optimizing process parameters, and following industry trends, enterprises can achieve efficient production and improve their market competitiveness. If you want to learn more about advanced rice bran oil expansion equipment and related technologies, click here to explore more!