In the dynamic landscape of the global edible oil market, sunflower oil has emerged as a highly sought - after commodity, driven by its health benefits and versatile culinary applications. As the demand for sunflower oil continues to soar, large - scale oil and grain enterprises are constantly on the lookout for efficient production methods to meet market needs while optimizing costs.

Traditional pressing methods have long been used in sunflower oil production. However, they come with inherent limitations. For instance, the oil extraction rate of traditional pressing is relatively low, often leaving a significant amount of oil in the residue. Moreover, these methods generally consume more energy and require a larger workforce, which leads to higher unit production costs. In large - scale industrial production, these limitations can become a bottleneck for enterprises aiming for high - yield and cost - effective operations.

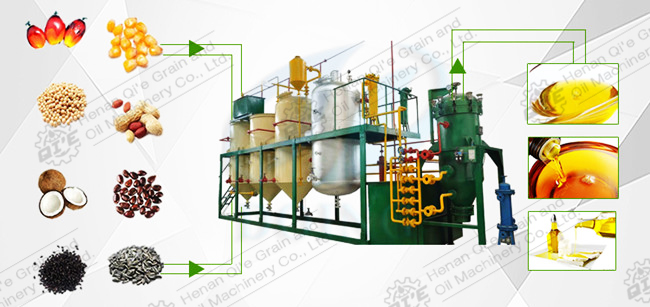

Hexane extraction technology, also known as solvent extraction method, has emerged as a revolutionary solution in the field of sunflower oil production. The principle behind this technology is based on the solubility of oil in hexane. When hexane comes into contact with sunflower seeds, it dissolves the oil, forming a miscella. This miscella is then separated and processed to obtain pure sunflower oil.

In large - scale production, hexane extraction technology offers several distinct advantages. Firstly, it significantly increases the oil extraction rate. Compared with traditional pressing methods, the oil yield can be increased by up to 10 - 15%. Secondly, it reduces energy consumption. The extraction process is more efficient, requiring less heat and mechanical power, which can lead to a notable decrease in unit energy consumption.

The hexane extraction process consists of several key steps. The first step is raw material pre - treatment, which involves cleaning, crushing, and flaking the sunflower seeds. Proper pre - treatment ensures that the seeds have an appropriate particle size and structure, which is crucial for efficient extraction. The second step is the design of the leaching equipment. Advanced leaching equipment is designed to ensure maximum contact between the hexane and the seeds, improving the extraction efficiency.

The third step is desolventizing control. After the extraction, the miscella needs to be separated from the hexane, and the hexane needs to be recycled. Strict desolventizing control not only ensures the quality of the oil but also reduces the loss of hexane. Safety regulations are also an integral part of the process. Hexane is a flammable and volatile solvent, so strict safety measures are required to prevent accidents.

Empirical data shows that the particle size distribution and oil content of sunflower seeds have a significant impact on the extraction efficiency. For example, when the particle size of the seeds is within a certain range (0.2 - 0.5 mm), the extraction efficiency can reach up to 95%. And when the oil content of the seeds is higher, the extraction process is more efficient, reducing the overall extraction time and energy consumption.

Let's take a look at a real - world example. A large - scale oil and grain enterprise adopted the hexane extraction technology using the Sunflower series solvent extraction equipment. After implementation, the enterprise achieved remarkable results. The unit energy consumption decreased by 18%, and the labor cost was reduced by 25%. According to the enterprise's feedback, The Sunflower series equipment not only improved our production efficiency but also brought us significant cost savings. The intelligent control system makes the operation more convenient and stable.

Environmental compliance and operational safety are of utmost importance in long - term operations. Hexane extraction technology, when properly implemented, can meet strict environmental standards. The recycling of hexane reduces waste and environmental pollution. At the same time, strict safety measures ensure the safety of employees and equipment, which is essential for the sustainable development of enterprises.

The Sunflower series solvent extraction equipment, with its intelligent control system, can monitor and adjust the extraction process in real - time, ensuring stable operation and high - quality output. It is designed to be highly efficient, reliable, and user - friendly, making it an ideal choice for large - scale sunflower oil production.

If you are a large - scale oil and grain enterprise looking to optimize your sunflower oil production process, reduce energy consumption, and cut labor costs, the Sunflower series solvent extraction equipment may be the solution you've been searching for. To learn more about how this technology can bring quantifiable energy - saving and cost - reducing value to your factory, click here.