In the rice bran oil industry, your expander isn’t just a machine—it’s the engine of efficiency. Many producers still run their equipment based on "what worked before," but in today’s competitive market, that approach leaves money on the table. In fact, we’ve seen clients achieve up to 20% higher yield and reduce energy consumption by 15–25% simply by fine-tuning three core parameters.

“If you're not optimizing temperature, pressure, and moisture control in your expander, you’re likely wasting both raw material and electricity.”

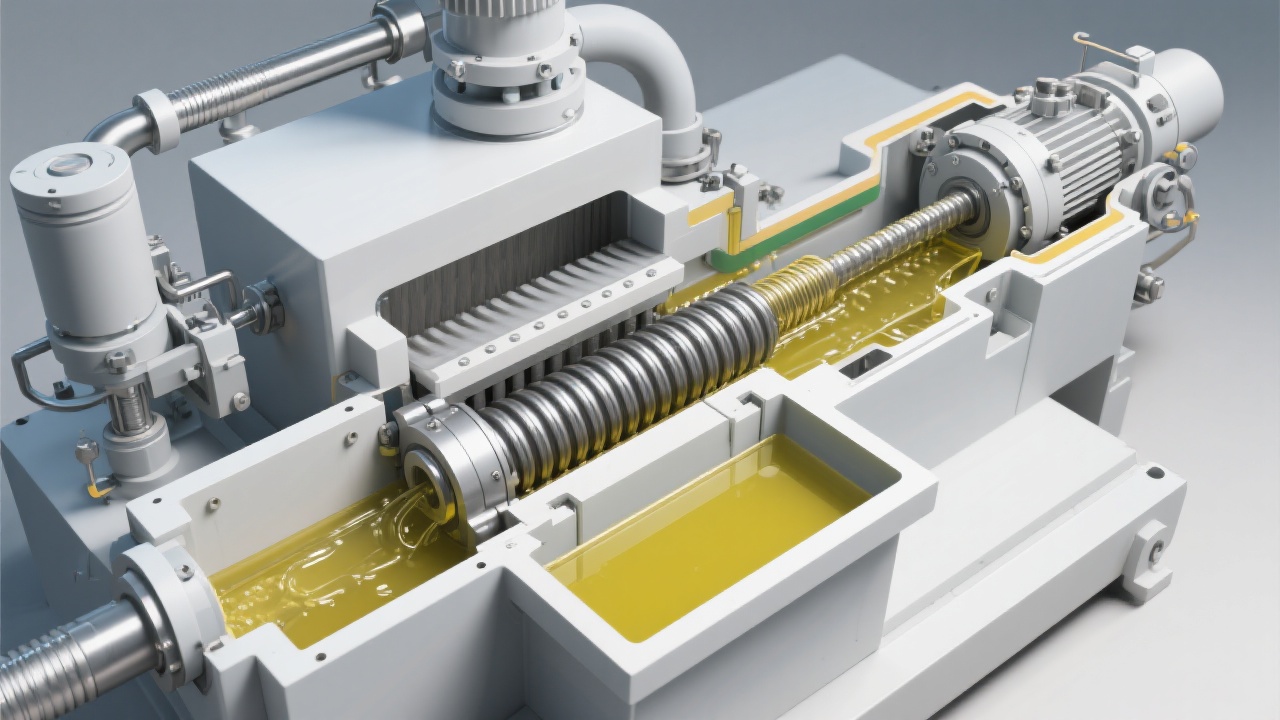

The expansion process physically ruptures cell walls in rice bran, releasing oil more efficiently. But if any parameter is off, you lose out:

| Parameter | Ideal Range (Typical) | Impact of Deviation |

|---|---|---|

| Temperature (°C) | 110–135°C | Too low → poor oil release; Too high → protein denaturation & clogging |

| Pressure (bar) | 1.5–2.5 bar | Low pressure → insufficient shearing force; High pressure → increased wear |

| Moisture Content (%) | 12–16% | Dry feed → brittle particles = low yield; Wet feed → reduced throughput & energy waste |

For example, one client in Vietnam had an average extraction rate of only 17%. After adjusting their moisture from 10% to 14%, they saw immediate gains—outlet oil content jumped to 20.5%, with no change in raw material input.

It’s not just about numbers—it’s also about durability. A standard carbon steel screw may last 6 months under heavy use, while a hardened alloy with ceramic coating can go over 2 years without major maintenance. One Argentine plant switched to tungsten carbide-coated screws and reported a 30% drop in downtime due to wear-related failures.

And here’s the kicker: when combined with automated real-time monitoring (like our smart PID controllers), even small adjustments become sustainable improvements—not one-off fixes.

Don’t wait for a breakdown to start optimizing. Start with this checklist:

Here’s what happens when you do it right: a Thai processor reduced their kWh/kg oil from 1.8 to 1.35—a saving of over $40,000 annually at 10 tons/day output.

掌握这3个关键参数,轻松让您的膨化机效率提升20%!