In the rice bran oil extraction industry, extrusion equipment plays a crucial role. It significantly impacts the overall oil extraction process and the final quality of the oil. For instance, a well - functioning extrusion machine can effectively break the cell walls of rice bran, which is essential for releasing the oil inside. This process not only improves the oil yield but also enhances the quality of the extracted oil.

However, many procurement officers, technicians, and production managers in the industry may not fully understand the importance and potential of this equipment. They might face challenges in choosing the right equipment and optimizing its operation. In fact, according to industry statistics, improper use of extrusion equipment can lead to a decrease in oil yield by up to 10%.

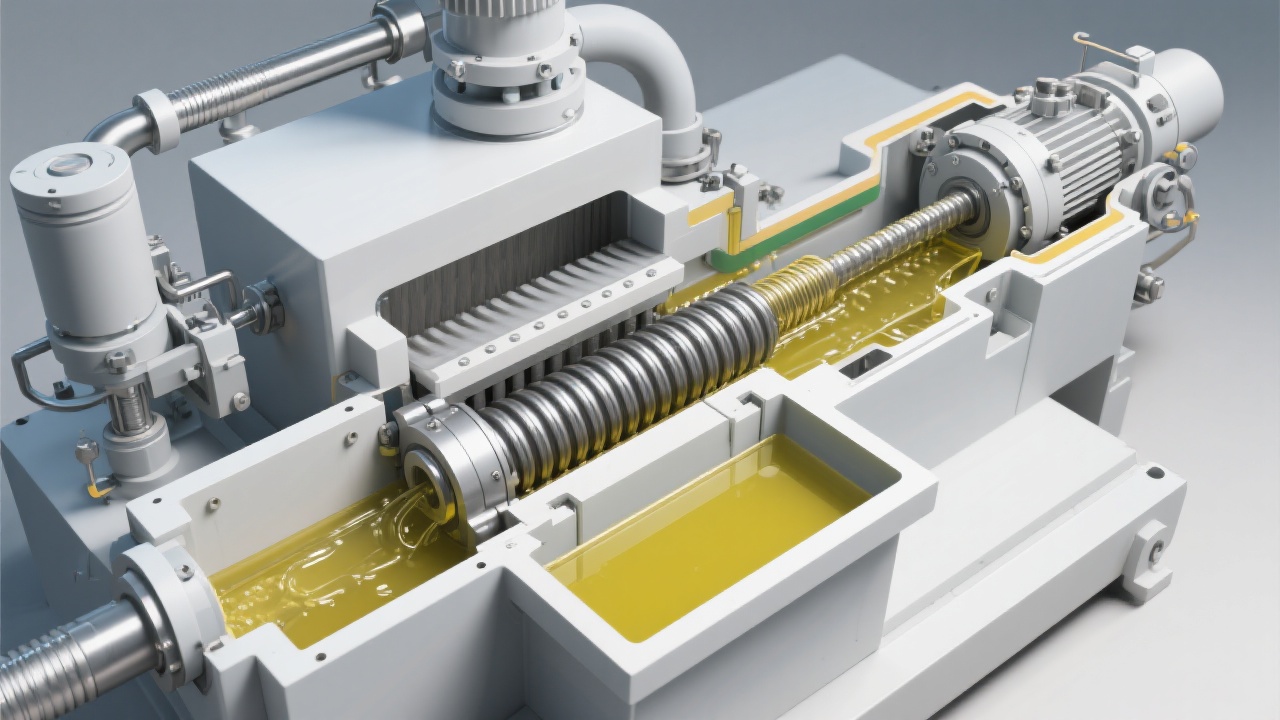

The working principle of the extrusion machine is based on the combination of mechanical force, heat, and pressure. Think of it like a powerful blender that not only mixes but also transforms the rice bran. When the rice bran enters the extrusion chamber, the screws inside rotate, generating high pressure. At the same time, the friction between the rice bran and the chamber walls produces heat. This combination of pressure and heat causes the rice bran to expand and break down its internal structure, making it easier to extract the oil.

Three key parameters - temperature, pressure, and moisture control - have a significant impact on the extrusion process. Temperature affects the physical and chemical properties of the rice bran. A proper temperature can ensure that the oil is released without being damaged. For example, if the temperature is too high, the oil may oxidize, affecting its quality. Pressure is also crucial. High pressure can break the cell walls more effectively, but excessive pressure may cause the equipment to wear out quickly. Moisture content in the rice bran needs to be carefully controlled. An appropriate moisture level can help in the expansion process. Industry experience shows that maintaining a moisture content of around 12 - 15% can achieve better extrusion results.

Different equipment materials and structural designs can have a profound impact on the extrusion effect. For example, some extrusion machines are made of high - quality stainless steel, which is corrosion - resistant and can ensure the hygiene of the oil extraction process. On the other hand, machines with a well - designed screw structure can provide more uniform pressure and better mixing, resulting in a more efficient extrusion process.

Let's look at some real - world cases. A company in Asia replaced its old extrusion machine with a new one made of high - grade alloy steel and a more advanced screw design. After the replacement, the oil yield increased by 8%, and the production efficiency improved by 15%. However, some low - cost equipment may use inferior materials, which can lead to problems such as rusting and uneven pressure distribution, ultimately affecting the quality and quantity of the extracted oil.

Before starting the equipment, it is necessary to conduct a thorough inspection. Check the lubrication of the screws, the tightness of the bolts, and the functionality of the electrical system. During operation, operators should monitor the temperature, pressure, and current of the equipment in real - time. If any abnormal situation occurs, the equipment should be stopped immediately for inspection.

Energy consumption is an important cost factor in the production process. To reduce energy consumption, operators can optimize the operation parameters of the equipment. For example, adjusting the rotation speed of the screws according to the actual production volume can save up to 15% of energy. Also, regular maintenance of the equipment can ensure its efficient operation and reduce unnecessary energy waste.

To increase the production capacity, companies can consider upgrading the equipment or optimizing the production process. For example, adding a pre - treatment device before the extrusion machine can improve the quality of the rice bran entering the extrusion chamber, thereby increasing the production capacity. In some cases, companies have achieved a 20% increase in production capacity through process optimization.

With the current trends of energy conservation, environmental protection, and intelligent manufacturing in the industry, rice bran oil extrusion equipment is also evolving. Future equipment is expected to be more energy - efficient, with lower emissions and a smaller environmental footprint. Intelligent features such as remote monitoring and automatic adjustment of parameters will become more common. For example, an intelligent extrusion machine can automatically adjust the temperature and pressure according to the moisture content of the rice bran, improving the overall efficiency and quality of the production process.

Manufacturers should focus on research and development to meet these future trends. Upgrading the equipment's control system, using more advanced materials, and improving the overall design are all important steps. By doing so, they can provide more competitive products to the market and help their customers achieve better production results.

If you are interested in learning more about our high - performance rice bran oil extrusion equipment and how it can bring value to your business, click here to explore our product range and get in touch with our experts.

Do you have any specific requirements or challenges in your rice bran oil production process? Share your situation with us, and we'll send you 3 industry - specific solution cases.