Supercritical CO2 extraction technology has emerged as an innovative and environmentally - friendly method for sesame oil extraction. This article offers a comprehensive guide, from basic principles to practical applications, aiming to provide industry users and technology decision - makers with professional and reliable technical knowledge.

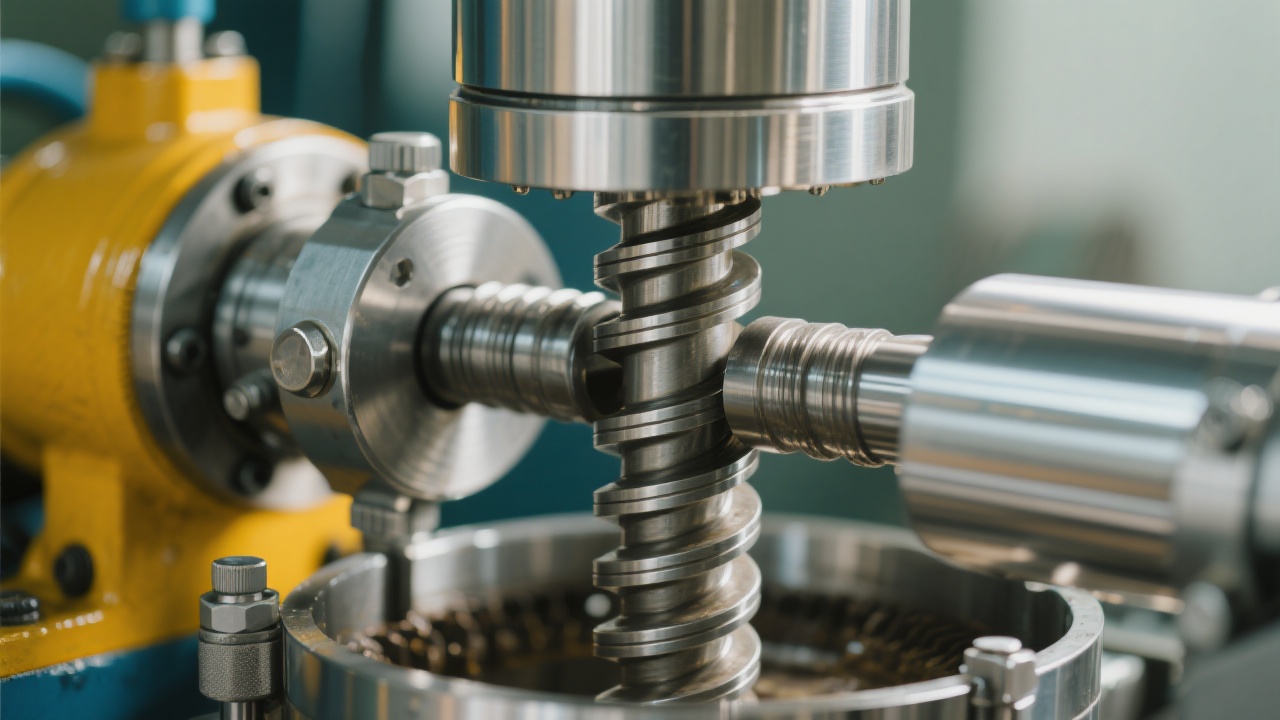

Supercritical CO2 extraction takes advantage of the unique properties of carbon dioxide in a supercritical state. Under specific temperature and pressure conditions (usually around 31.1°C and 7.38 MPa), CO2 enters a supercritical state where it exhibits both gas - like diffusivity and liquid - like solvating power. In this state, CO2 can penetrate sesame seeds effectively and dissolve the oil within them. Once the extraction is complete, reducing the pressure allows the CO2 to return to a gaseous state, leaving behind pure, solvent - free sesame oil.

Temperature plays a crucial role in supercritical CO2 extraction. Generally, within a certain range (e.g., 40 - 60°C), an increase in temperature can enhance the solubility of oil in supercritical CO2, thus improving extraction efficiency. However, if the temperature is too high, it may cause thermal degradation of some heat - sensitive components in sesame oil, affecting the oil quality. Research shows that at a temperature of 50°C, the extraction efficiency can reach up to 90% in some cases.

Pressure also significantly impacts the extraction process. Higher pressure (e.g., 20 - 30 MPa) can increase the density of supercritical CO2, which in turn enhances its solvating power. But excessive pressure will increase energy consumption and equipment requirements. For example, when the pressure is set at 25 MPa, the extraction rate of sesame oil can be optimized while maintaining a reasonable energy cost.

The extraction time is another important factor. Longer extraction times usually lead to higher extraction yields. However, after a certain period, the increase in yield becomes negligible, and it may also increase production costs. Typically, an extraction time of 2 - 3 hours can achieve a relatively high extraction rate.

| Extraction Method | Cost | Environmental Impact | Oil Quality |

|---|---|---|---|

| Supercritical CO2 Extraction | Higher initial investment in equipment, but lower long - term operating cost due to no solvent consumption | Environmentally friendly, no solvent residue | High - quality, retains more natural nutrients and flavor |

| Hydraulic Pressing | Lower equipment cost, but lower extraction efficiency, higher labor cost | Relatively low environmental impact | Good quality, but some nutrients may be lost during pressing |

| Solvent Extraction | Low cost, but requires solvent recovery system, increasing overall cost | Potential environmental pollution due to solvent use | May have solvent residue, affecting oil quality |

In the context of sustainable development, supercritical CO2 extraction technology for sesame oil has broad industry potential. Consumers are increasingly demanding high - quality, natural, and environmentally friendly food products. This technology can meet these market demands by producing high - quality sesame oil with excellent flavor and nutritional value. It also has the potential to be applied in other industries such as cosmetics and pharmaceuticals.

Now, we have a question for you: Do you think supercritical CO2 extraction technology will completely replace traditional sesame oil extraction methods in the future? Share your thoughts in the comments below!

Interested in learning more about supercritical CO2 extraction technology? Discover detailed insights and real - world applications by visiting our technology white - paper专区.